Practice-based Research Publication

Throughout this term, I've been working in the DigiLab with the 3D printers. This was, with the emphasis on was, a new experience for me since I've never worked with these machines before. I grew in this working space as it now feels like home, which I am proud of and happy with. Before the midterms, I was inspired and intrigued by the foldings of a print and how this folding can have an additional value. Short after the midterms, I started printing on fabric which resulted in a new practice-based process.

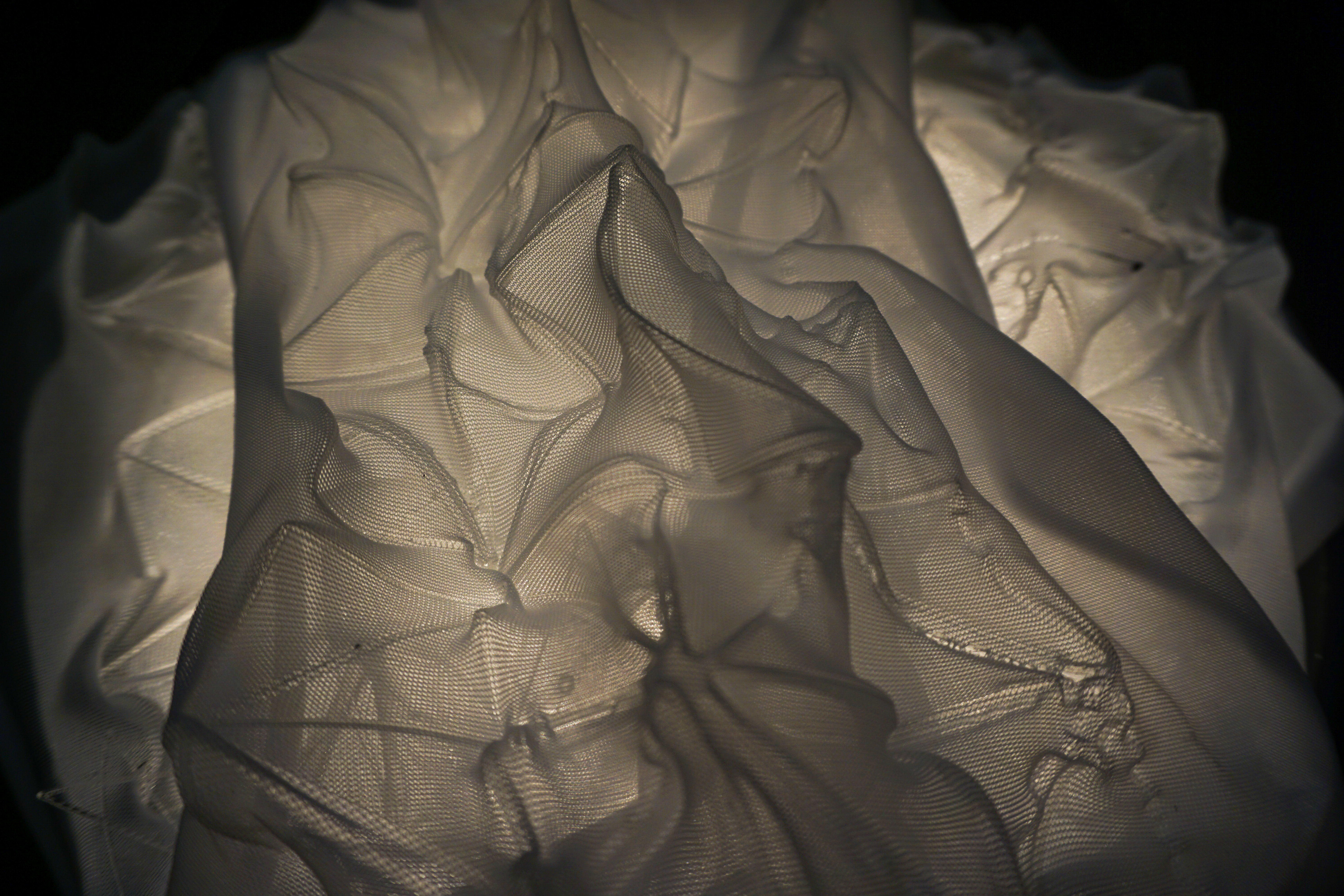

I questioned myself if it was possible to let the print fold itself or gain some sort of form after printing. I found out that when you stretch out a piece of fabric the tension can get caught by printing a single layer. I bought pantyhoses as my material and got some good results right away. When I tried to recreate it I encountered some problems with the material and the printer as I then persisted on different materials. In the end; a combination of material choice, the placement of the fabric and thereby stretching the material solved these problems which resulted in outstanding samples and new key insights.

To avoid earlier problems, I decided to make some moulds with a diameter of 15 and 23 centimetres in which the material is stretched identically so each print will succeed. With these moulds, I can take one particular part of a piece of fabric and transform this with the printing technique I developed. But can I go bigger? The maximum printing size of the Ultimaker Original is 20x20 centimetres but since the printer has open sides I can use it more or less as a sewing machine by pushing through a mould and thus fabric. The final mould is 2 meters long and 20 centimetres in width. Because I can print 20x20cm each time I 'sliced' the mould and graphic in ten pieces each representing one print.

All in all, I would say my end product is not in per se the last outcome, the 'scarf', but more the technique that I've conquered. The use of the 3D printer to transform/manipulate the fabric from flat material to an interesting three-dimensional form, the understanding of the process and the final mould production are my realised works. The practice-based research suits me very well as I discover a lot during the process by just making. I'm ending this term with a to be continued since I think this technique has a lot of potential yet still needs to be improved. In this second research, I would like to think more about colours and the additional value this manipulation of the fabric can have on products.